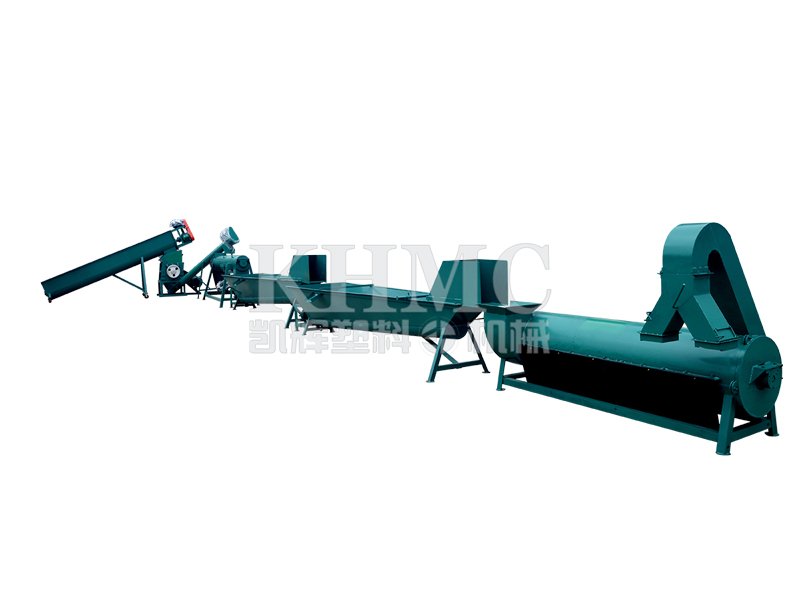

Best-Selling Pp Strap Band Extrusion Line – Multifunction Plastic Extruder Monofilament Making Machine – Kaihui Machinery

Best-Selling Pp Strap Band Extrusion Line – Multifunction Plastic Extruder Monofilament Making Machine – Kaihui Machinery Detail:

Technical Parameters

| Type |

SYP(T/A)-M65 |

SYP(T/A)-M80 |

SYP(T/A)-M90 |

SYP(T/A)-M110 |

SYP(T/A)-M125 |

|

| Screw Diameter(mm) |

65 |

80 |

90 |

110 |

125 |

|

| Gross power(kw) |

90 |

100 |

130 |

150 |

170 |

|

| Actual power consumption (kw) |

40 |

50 |

65 |

70 |

85 |

|

| Productivity(kg/h) |

PP |

30-50 |

40-70 |

60-90 |

100-140 |

100-140 |

|

PET |

50-70 |

80-90 |

100-125 |

130-160 |

160-200 |

|

| Dimensions(m) |

L: 20-25, W: 2-3, H: 2-3 |

|||||

|

It can be designed according to workshop size. |

||||||

| Total weight(t) |

7.5 |

8.2 |

9.6 |

10.8 |

12.8 |

|

Function

The monofilament extrusion line is widely used to make different types of filaments, like rope filament, trimmer line, fishing line, builder line, grass cutting line, safety net, fishing net, vineyard wire, etc.

Product Video

About Raw Materials

This machine is suitable for different materials like PP, PE, PET, PA. At present, PET recycled flakes are the most popular materials used by customers in most regions due to its wide source and low price of raw materials (waste water bottles) as well as strong tensile strength and anti-aging of the finished products. It is gradually replacing PP PE raw materials, but PP PE PA still has their unique advantages in making different products. For example, for trimmer lines, PA is the best choose. You can choose raw material according to the finished product requirement, material price difference and the specific needs of the local market. We will be very glad to provide suggestions.

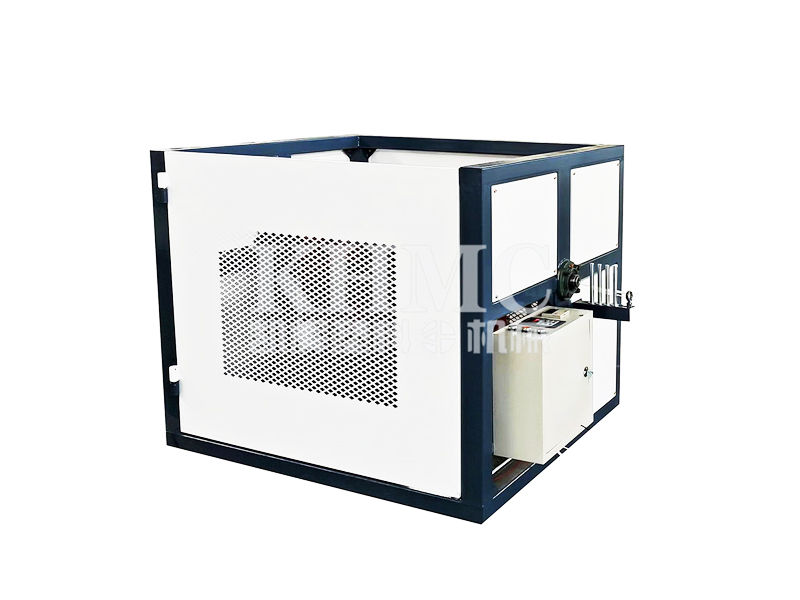

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Best-Selling Pp Strap Band Extrusion Line – Multifunction Plastic Extruder Monofilament Making Machine – Kaihui Machinery , The product will supply to all over the world, such as: New Delhi, Danish, Atlanta, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!