China Coil Winding Machine Factory – High Efficiency Plastic Recycling Granulator Machine – Kaihui Machinery

China Coil Winding Machine Factory – High Efficiency Plastic Recycling Granulator Machine – Kaihui Machinery Detail:

Technical Parameters

|

Type |

SJ-125/S |

SJ-125/D |

SJ-150/D |

SJ-180/D |

SJ-210/D |

|

Screw size |

125mm |

125mm/125mm |

150mm/125mm |

150mm/150mm |

210mm/180mm |

|

Extruder |

Single |

Double |

Double |

Double |

Double |

|

Main motor power |

30kw |

22kw |

45kw |

75kw |

110kw |

|

11kw |

22kw |

30kw |

45kw |

||

|

Reducer |

200 |

200 200 |

250 225 |

280 250 |

325 280 |

|

Filter |

Manual filter / electric filter |

Hydraulic filter |

|||

|

Capacity |

3000kg |

3000kg |

5000kg |

8000kg |

10000kg |

|

Machine Size |

3000*2000*1000 |

3000*2500*1500 |

3500*3500*2000 |

5000*4000*2000 |

7000*5000*2000 |

|

Crusher, automatic loader, washing machine, moving silo can be provide if you need . |

|||||

Equipment and Services

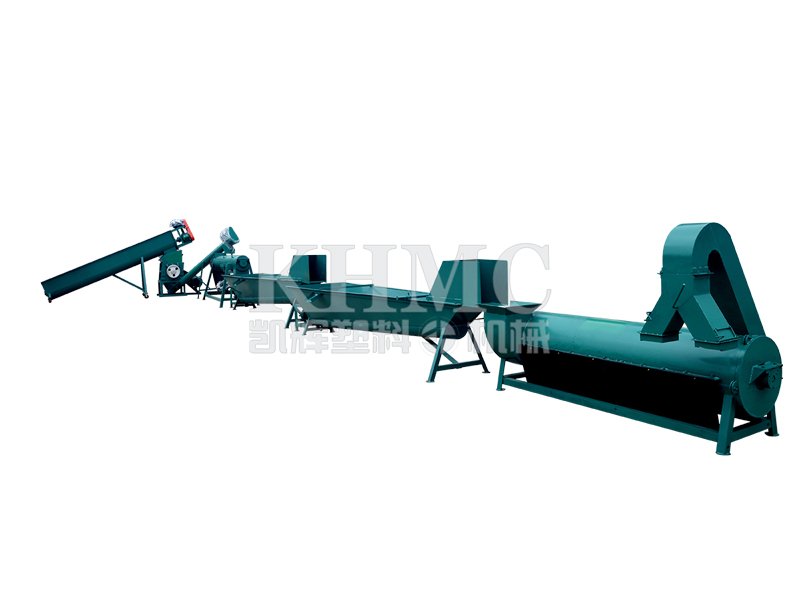

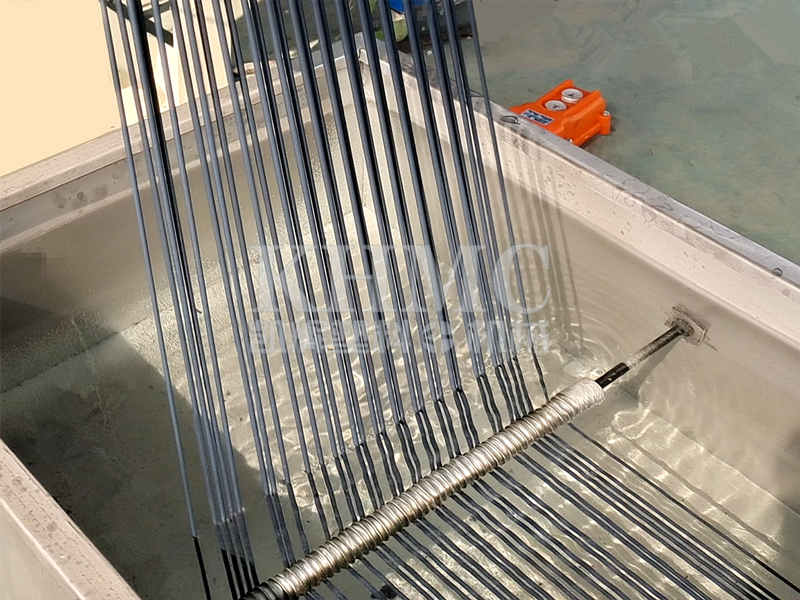

Our plastic granulation machine is to make granules by a process of crushing—washing—melting—extruding—cutting—storing. While providing automatic cleaning equipment, our company can also provide customers with factory self-built cleaning pool solutions to save transportation costs.

Product Video

More Choices

Our company can produce machines with equipment capacity ranging from 2 tons to 12 tons, from simple equipment to high-end machines, which can meet the requirements of most customers. The optimal solution can be designed and customized according to the customer’s raw material types and production capacity requirements.

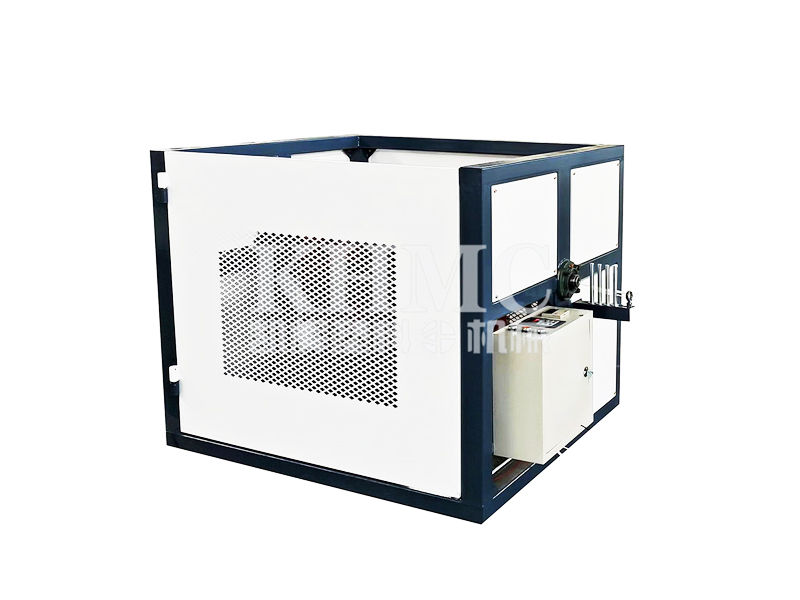

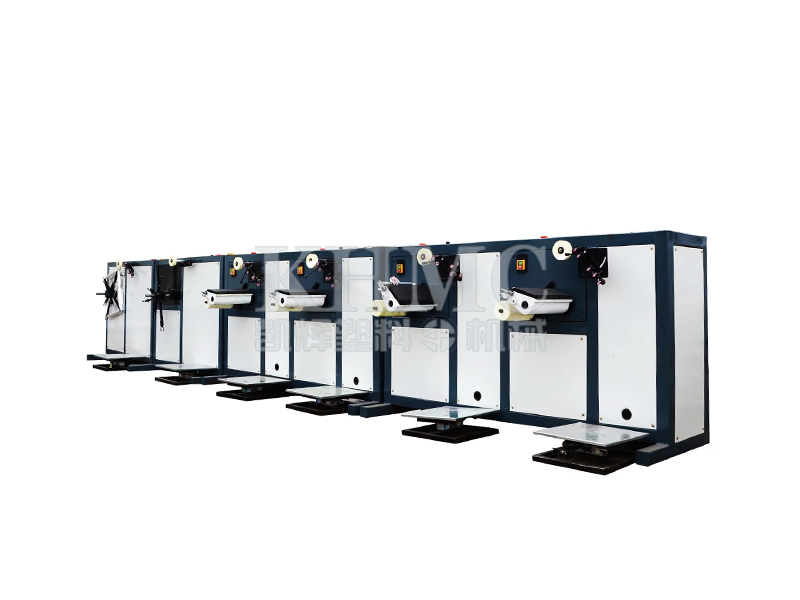

Single-step granulator, two-step granulator and three-step granulator are optional. At the same time, in terms of equipment configuration, ceramic heating, cast aluminum heating, electromagnetic energy-saving heating are optional; electric screen changer, hydraulic single-screen screen changer, and hydraulic uninterrupted screen changer are optional. Various functions such as automatic feeding, intelligent temperature control, automatic pressure sensing slag discharge (impurities), automatic water circulation cooling, automatic material storage and other functions are optional, with a high degree of automation, helping customers to increase production and efficiency.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of China Coil Winding Machine Factory – High Efficiency Plastic Recycling Granulator Machine – Kaihui Machinery , The product will supply to all over the world, such as: Albania, Haiti, Sacramento, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!