Danline Rope Machine Manufacturer – Production Line of Reinforced Macro Fiber for Concrete – Kaihui Machinery

Danline Rope Machine Manufacturer – Production Line of Reinforced Macro Fiber for Concrete – Kaihui Machinery Detail:

Technical Parameters

| Type |

H-CFE-65 |

H-CFE-80 |

H-CFE-90 |

H-CFE-110 |

H-CFE-125 |

| Screw Diameter(mm) |

65 |

80 |

90 |

110 |

125 |

| Gross power(kw) |

90 |

100 |

130 |

150 |

170 |

| Actual power consumption (kw) |

40 |

50 |

65 |

70 |

85 |

| Productivity(kg/h) |

40-60 |

60-80 |

80-100 |

100-125 |

125-140 |

| Dimensions(m) |

L: 18-25, W: 2-3, H: 2-3 |

||||

|

It can be designed according to workshop size. |

|||||

| Total weight(t) |

6.5 |

7.2 |

8.6 |

9.8 |

11.8 |

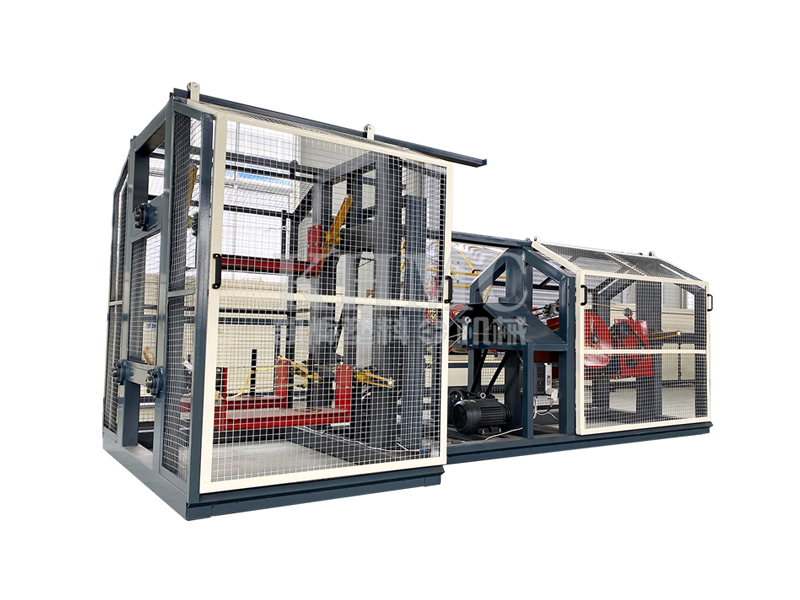

Production Process

The production line uses PP PE as the raw material, which is heated and melted, drawn, then cooled, then heated and stretched by the extrusion line. Special devices can also be added, like embossing device, netting device, and devices with other special treatments to make the finished product take on different shapes. The extrusion line cooperates with the cutting machine, sometimes, as well as twisting machine, to obtain the final product. The equipment is easy to operate, and only one person is required for each process. Our company provides a full set of technical support and after-sales service to ensure smooth production for customers.

Finished Product

This extrusion line is to make fiber for concrete. The combination of fiber and concrete substrate improves the inherent weakness of concrete and has various effects on concrete performance. The improvement of crack resistance and durability of fiber reinforced concrete is of great significance to the construction of high-quality, beautiful and durable projects.

![]()

Advantages

KHMC has about 30 years’ experience in manufacturing of all types of PP, PE, PA, PET extrusion lines. After continuous improvement to our equipment, our machinery has the advantages of cost-effective, stable production, high efficiency, energy saving with low power, easy operation, etc. The concrete fiber produced by our machine has the characteristics of good dispersion, strong gripping force and strong pulling force.

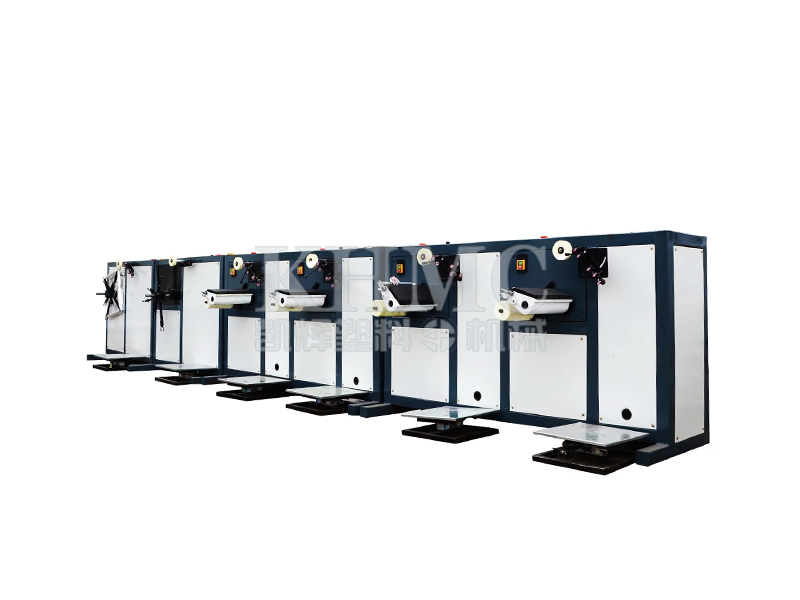

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Danline Rope Machine Manufacturer – Production Line of Reinforced Macro Fiber for Concrete – Kaihui Machinery , The product will supply to all over the world, such as: Barbados, Birmingham, Iraq, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our items and services, please do not hesitate to contact us!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!