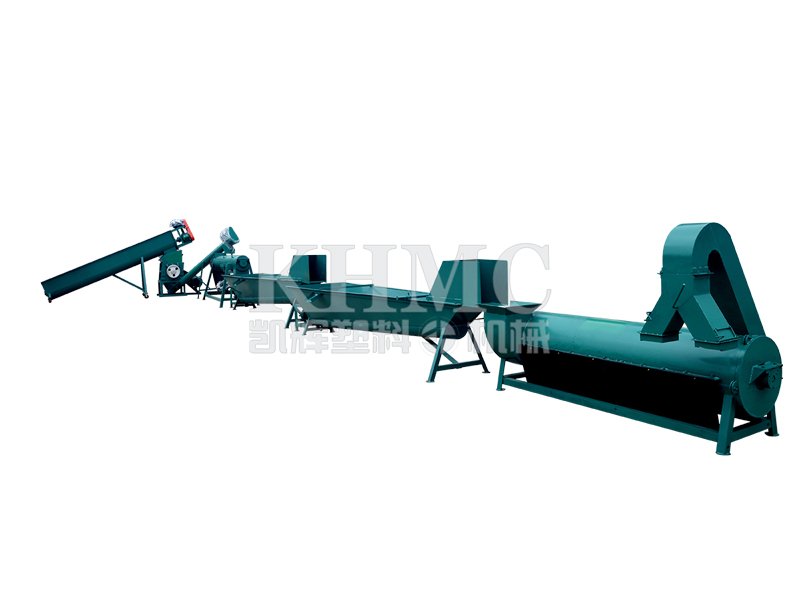

High-Quality Trimmer Line Machine Factory – Long-Lasting Plastic Blowing Machine For PP Twine & PE Tying Tape – Kaihui Machinery

High-Quality Trimmer Line Machine Factory – Long-Lasting Plastic Blowing Machine For PP Twine & PE Tying Tape – Kaihui Machinery Detail:

Technical Parameters

| Type |

KHSJ-B65 |

KHSJ-B80 |

KHSJ-B90 |

KHSJ-B110 |

| Screw Diameter(mm) |

65 |

80 |

90 |

110 |

| Gross power(kw) |

60 |

70 |

80 |

90 |

| Actual power consumption (kw) |

30 |

35 |

40 |

45 |

| Productivity(kg/day) |

1000 |

1500 |

2000 |

3000 |

| Dimensions(m) |

16×3×5 |

18×3×5 |

20×3×5 |

22×3×5 |

| Total weight(t) |

4.5 |

5.5 |

6.5 |

7.5 |

Function

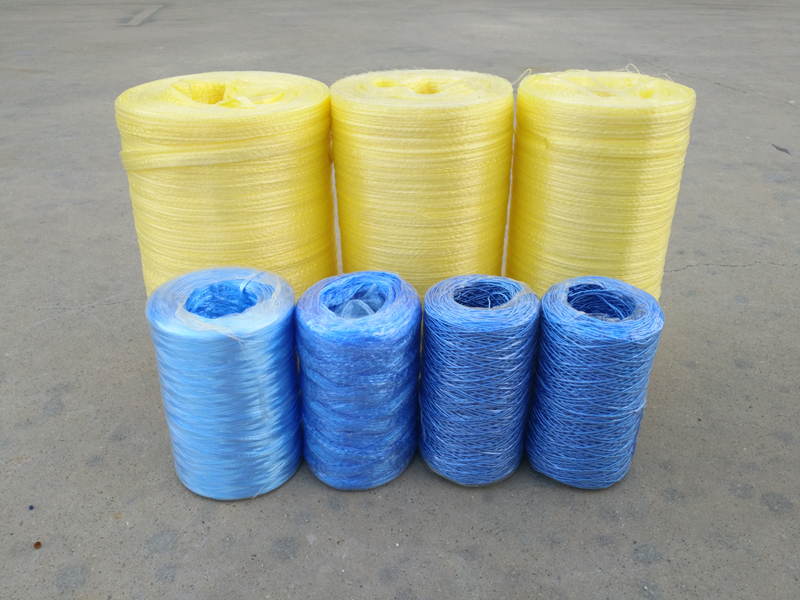

Finished products of this machine are used to make all kinds of ropes including packing rope, agricultural twine, industry twine, automatic tying tape, etc. The production line can work with ball winder or bobbin winder to make the baler twine into ball or spool shape. It can also work with twisters to make twisted twine, which can further made into twisted twine ball or twisted twine spool. The tying tape can work on the balers directly for packing and reduce the labor cost.

Product Video

Advantages of Equipment

The plastic blowing machine made by our factory is multifunctional and cost-effective. Our equipment has improved the foaming process, hemming process, and embossing process, so that the finished products can present a richer form to meet the market needs of different countries around the world. The equipment is also suitable to make tying tape which can be used in automatic balers, which can save labor more effectively and are widely used in airports and packaging industries. At the same time, our company can produce two-color plastic twine by transforming the core parts such as extruder mold, which is welcomed by customers as a new product.

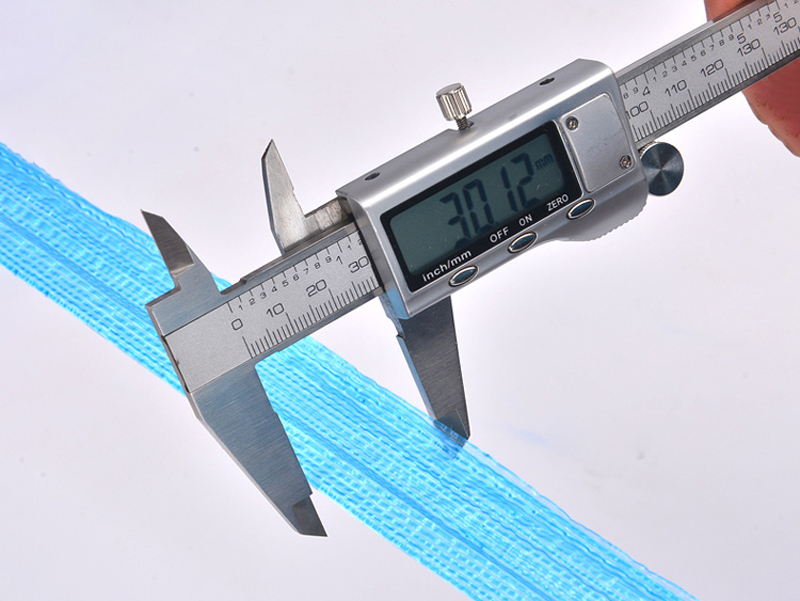

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for High-Quality Trimmer Line Machine Factory – Long-Lasting Plastic Blowing Machine For PP Twine & PE Tying Tape – Kaihui Machinery , The product will supply to all over the world, such as: Costa rica, Brunei, Romania, Our Company has qualified engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the items, Be sure to feel free to contact us.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.