2.2 Nylon fiber concrete

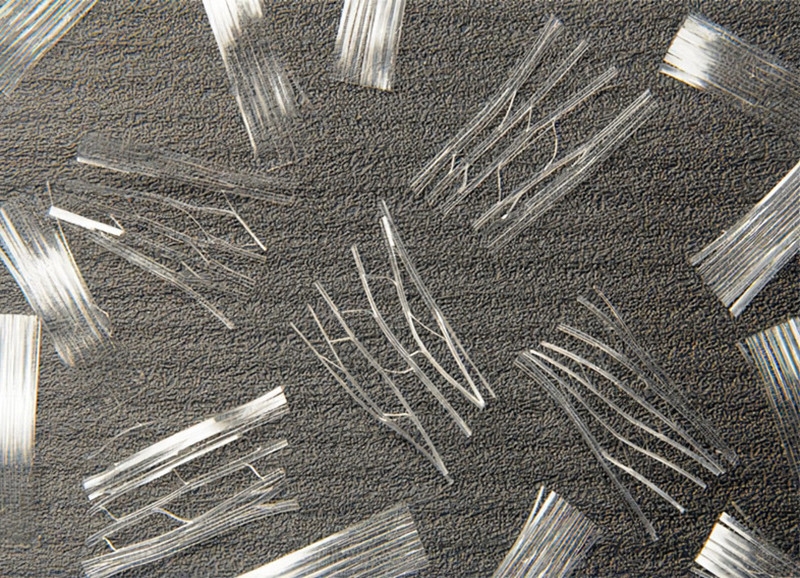

Nylon fiber concrete is one of the earliest polymer fibers used in cement and concrete, the price is relatively high, and the application is limited. The incorporation of nylon fiber can significantly reduce the dry shrinkage value of concrete, but the flexural, compressive, axial pressure, elastic mold and stress-strain properties are not significantly different from ordinary concrete, and the impermeability and rust inhibition performance are significantly improved, thereby improving the durability of concrete.

When a small amount of nylon fiber (0.052%) is added to the concrete, the concrete matrix can obtain a significant non-structural performance enhancement effect, greatly reduce the plastic shrinkage cracks of concrete, and improve the impact resistance of concrete. When the dosage is increased to 0.26%, the impact resistance of concrete can be greatly increased. Nylon fiber can improve the frost resistance of concrete, inhibit the energy loss of concrete, and improve the appearance of the test piece. Wan Zhongxiang et al. believe that this is due to the incorporation of nylon fibers to reduce the cracks caused by the internal stress of concrete, as well as the increase in the gas content of concrete, and the increase in anti-expansion pressure and osmotic pressure. They found that concrete doped with 0.5% volume fractional nylon fiber reduced the dynamic elastic modulus loss and mass loss by 10.5% and 1.7%, respectively, compared with the benchmark concrete after 300 freeze-thaw cycles.

2.3 Polyethylene fiber concrete

Due to its low modulus of elasticity, polyethylene fiber has been rarely used in cement composites so far, and it has been poorly studied. K.C. G. Ong, M. Basheerkhan, P. Paramasivam in the low-speed impact test of polyethylene fiber concrete slab, in the fiber content of 0.5%, 1% and 2%, the fracture energy value increased by 19%, 53% and 80%, respectively. Although these values are smaller than the values of steel fiber concrete slabs of the same content (the values of steel fiber concrete slabs are 40%, 100% and 136%, respectively), their price is much smaller than steel fiber, if the elastic modulus of up to 70GN/m2 can be developed high elastic mold polyethylene fiber, this cheaper fiber has great potential in the field of cementitious composites.

Laizhou Kaihui Machinery Co.,Ltd is a professional manufacturer of concrete fiber extrusion line. Welcome to contact us to get more information.

Post time: Nov-23-2022